In order to let the customers learn more about the multiple kinds of raw materials of mobile phone stickers, we specially prepare this series of articles. If you have any question, please leave a message and your contact information on the bottom of this page. We will get back to you soon.

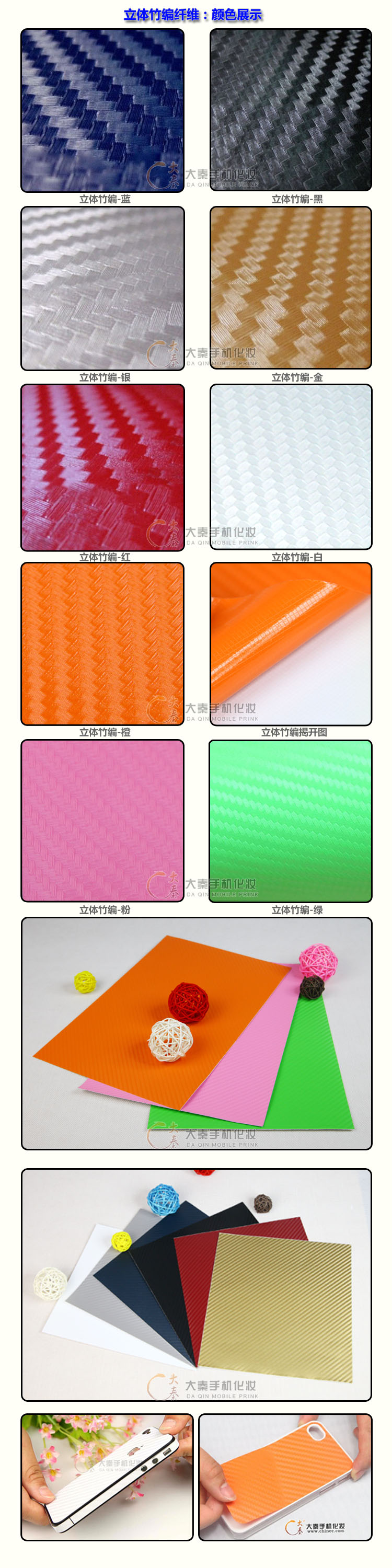

We’ve introduced lots of cutting films to make mobile phone stickers in previous articles in previous articles already. Now let’s have a look at the 3D water drops film materials, which are popular materials that used for cutting into custom cellphone stickers for any model cellphone phone by Daqin 3D mobile skin designing and making system.

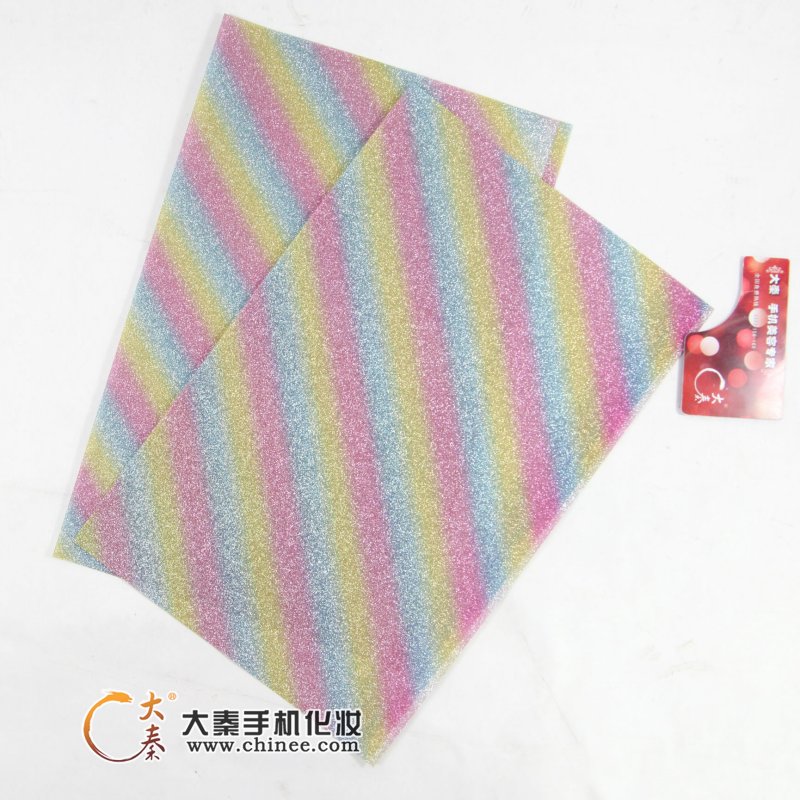

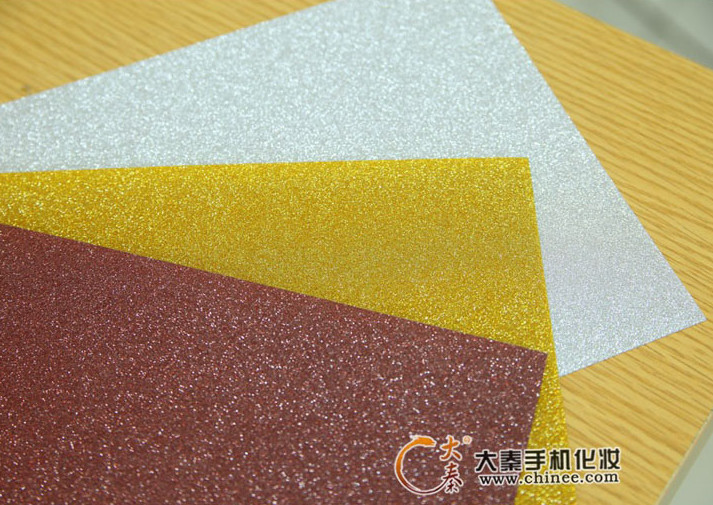

The 3D water drops films are with multiple colors to choose from. The mobile phone stickers made of such material are with amazing 3D effect, which looks like shining water drops. When put it in the sunlight, the shining 3D water drops effect is amazing. In ordinary environment such as in the office, it will also shining like water drops.

In the hot summer, apply the 3D water drop effect mobile phone sticker to your smartphone, and then the vividly shining 3D effect will bring you a cool feeling. The colorful 3D water drops films are opaque material, as a result, it’s suitable to be applied on mobile phone of any color. With the help of the Daqin 3D mobile phone skin designing and making system, any model of smartphone in the world can get its own custom mobile phone sticker with 3D water drops effect.

Within 1 minute, the cutter of the Daqin 3D mobile phone skin designing and making system can cut the film according to the highly accurate cutting templates in the Daqin 3D mobile beauty master software to get a well-cut sticker. The well-cut sticker will fit with the smartphone, looks as if the sticker is part of the original phone.

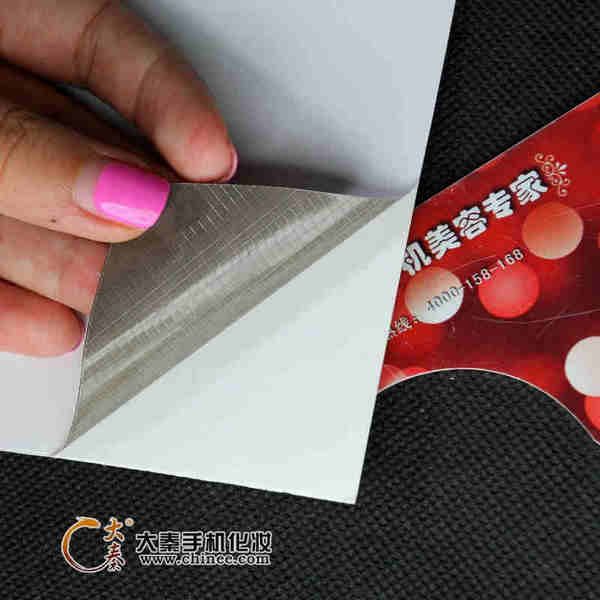

On the sticky side of the 3D water drops film material, there are plenty of blowholes which can effectively avoid bubbles while manually apply the sticker to the mobile phone cover. Also, during the application process, if you happen to apply it to the wrong part, it’s easy to peel it off and then apply it again correctly until satisfied.

Although with excellent 3D effect, the price of the film is comparatively cheap; however, the sales price of the 3D water drops effect mobile phone sticker can be 20 to 40 times of the cost price or even more, nice profit indeed.